KVX Versatility and Optimization

1. One Lip, Several Configurations

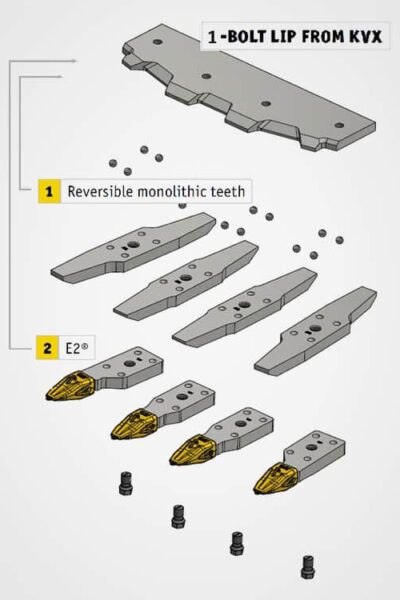

The KVX solution is special because the tooth system is bolted on the cutting edge (lip). This configuration is weld-free, which means less downtime and the possibility to freely switch between several KVX GET solutions. If a machine is moved from one application to another, you can easily adapt/change the GET system to a more optimal solution. If you change operators and they prefer a different configuration, you can easily adapt to their needs. Easily and quickly !

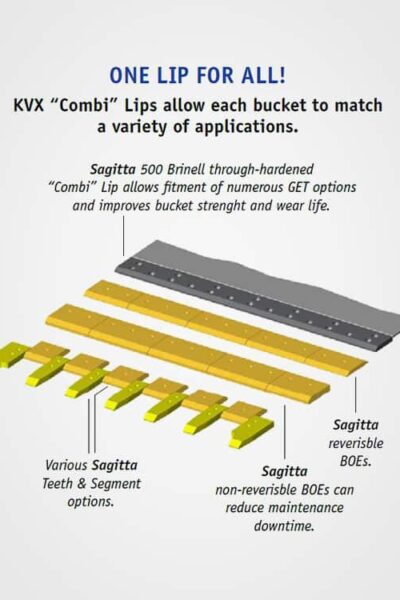

The bolt-on concept/Combi lip concept gives a great opportunity to tailor a lip/GET set up based on standard components. Our modular concept is suitable for several models of lips (straight, delta, pointed). We can supply many solutions on few standard components.

- One Excavator Lip – several teeth concepts KVX Classic “monolithic” system, E2® system and Intruder system* are interchangeable on the same lip. When moving a bucket from one application to another you don’t need a new bucket or changing of weld on adapters – you just bolton a new GET configuration (*depending size of machine)

- KVX wheel loader lips can be equipped with a variety of bolt-on GET options to best match operating conditions. Length, width and thickness can be adjusted according to wear pattern, all on the same lip.