Wheel Loader Lip Systems

Four different layouts are available, designed to cover all applications including the most severe conditions. Standard components are used whenever possible, with tailor-made solutions developed for special requirements.

- Cutting Edge Without Hole

- Cutting Edge With Wear Plates Only

- Cutting Edges With Teeth & Segments

- Serrated Lip

Applications:

- Surface Mining

- Tunneling

- Quarrying

- Construction

- Utility System

- Hot Slag

- Road/Rail

Machine Type:

- 0-300 Wheel Loaders

- KVX M16-M90

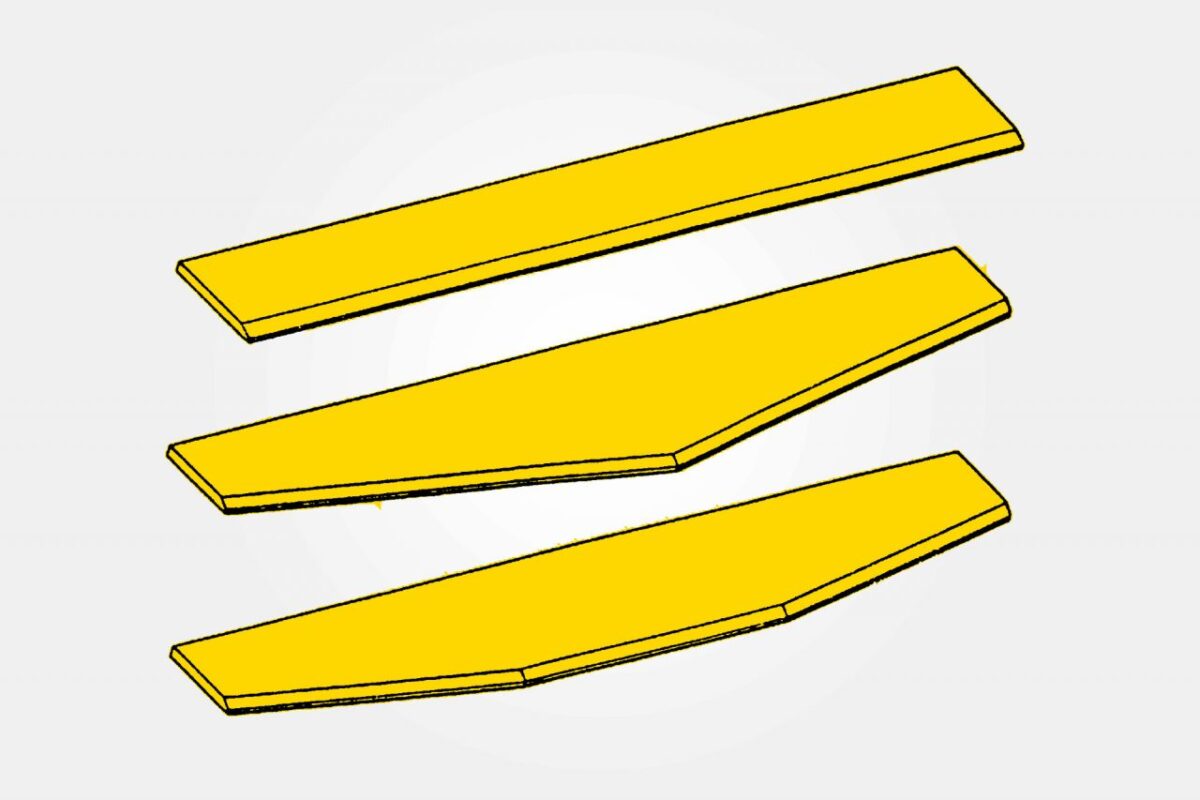

Cutting Edge Without Hole

Straight, pointed, spade and profiled cutting edges without holes. Low weight and good penetration.

- Straight cutting edge

- Pointed cutting edge

- Spade cutting edge

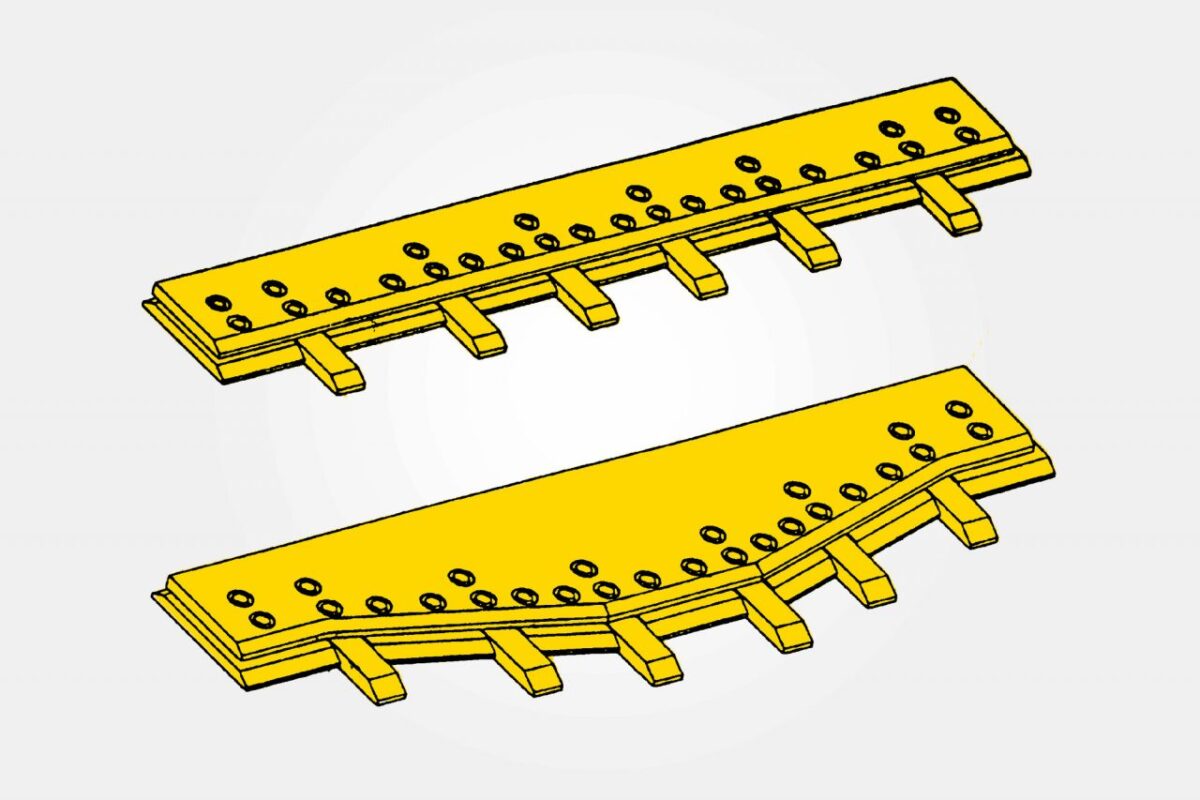

Cutting Edges With Teeth & Segments

Combi system: A perfect combination of teeth and wear plates for especially abrasive and severe conditions. Note that selection of a Combi lip, also allows the fitment of wearplates only should your application change… a significant enhancement to versatility.

- Straight cutting edge

- Spade cutting edge

For Limestone: Straight and spade edges with bolt-on teeth and wear segments special hardly heat treated for limestone conditions to avoid thermal cracking.

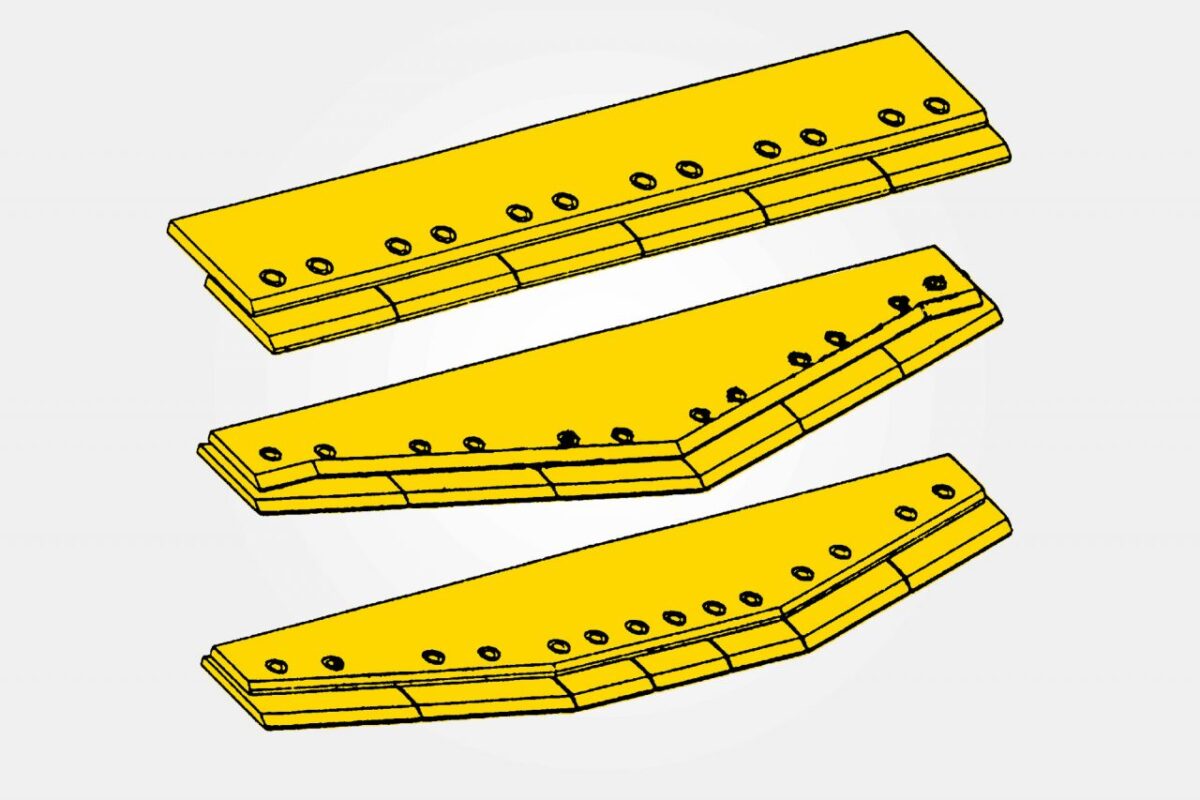

Cutting Edge With Wear Plates Only

General purpose cutting edges in straight, pointed and spade edge configuration for sand, gravel and tunnel loading.

- Straight cutting edge

- Pointed cutting edge

- Spade cutting edge

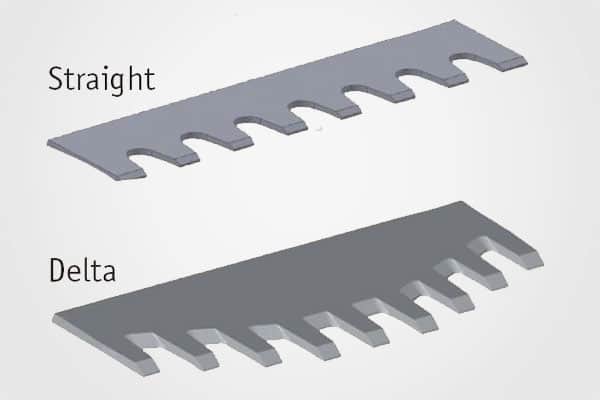

Serrated Lip

KVX system for Limestone and other softer materials like coal and bauxite

- Straight cutting edge

- Spade cutting edge